Albacore Park hopes newest marine propeller inspection software will spark interest in STEM careers

The USS Albacore is housed at Albacore Park in Portsmouth and is a National Historic Landmark. (Courtesy of Albacore Park) BY EMILY REILY

Educational

outreach has always been a cornerstone of the mission at Albacore Park,

a national historic landmark in Portsmouth that houses the USS

Albacore, an experimental research submarine built by workers at

Portsmouth Naval Shipyard in Kittery in 1952 and launched by the U.S.

Navy the following year.

So

when a member of TrueProp Software — a local marine propeller

inspection company in Newmarket — requested permission to take a 3D scan

of the Albacore’s former 14-foot-diameter propeller as a case study,

they were on board for the experiment.

“Our

first goal was to show that TrueProp can inspect very large propellers

on-site with minimal equipment,” says TrueProp Chief Technical Officer

Adam Kaplan.

Although TrueProp had used their technology on other propellers, the Albacore’s would be the largest they had ever scanned.

“In New England here, we have a lot of lobster boats.

We don’t have a lot of container ships. So finding a large propeller around here is pretty dope,” says Kaplan.

And

it didn’t hurt that Albacore Park’s then-director of education Nan

Bulger also shared an interest in learning more about the most

up-to-date technological advancements in propeller inspection,

diagnostics and repair.

“Being

an engineer who used stereolithography back in the early ‘90s, I was

well in tune with the progression of the technology,” says Bulger,

referring to the 3D printing process.

Bulger,

who has a mechanical engineering, consulting and nonprofit background

and built STEM programming for the park, says the Albacore was perfect

for TrueProp’s goal.

“It was just sitting there waiting for this opportunity.

We went out in the dead of winter and he did all of the scanning with his team,” Bulger recalls.

The

team scanned the surface of the 14-foot diameter propeller in two hours

using handheld 3D scanners that use a grid of blue-light lasers to take

a video. TrueProp’s software generated a report that detailed the

propeller’s condition, confirming a noticeable “fist-sized dent” at the

tip of a blade. No repair was needed, as the submarine is in a museum

setting.

Kaplan got the idea to contact Albacore Park after scanning the propeller on a UNH research vessel that had been decommissioned.

And

as Bulger sought more STEM (science, technology, engineering and

mathematics) outreach and other educational opportunities for Albacore

Park, it seemed like the perfect fit.

“Propellers

are also very complex designs (if you are an engineer). A propeller has

many sloping surfaces and so it is difficult to duplicate. 3D scanning

allows you to build an exact model of the structure,” says Bulger.

One aspect of STEM education includes understanding buoyancy and ballast.

“Why

does a submarine float and submerge? Why do large ships float? There is

a science and a math component to these questions. We apply those STEM

questions to every aspect of what we are studying,” Bulger says.

“Nan

was super on board. She totally speaks my language. She’s really big

with STEM outreach,” says Kaplan, who also sees the opportunity to teach

others about STEM careers and the latest innovations in the marine

propeller inspection industry.

“We

do a lot of support and training; we do a lot of trade shows,

professional organizations. The more that we can engage with the

up-and-coming generation to get them interested in maritime industries,

it’s a worth while endeavor,” says Kaplan.

TrueProp

hopes the experiment catches the interest of visitors to Albacore Park,

where the public can learn about the USS Albacore’s storied history as a

research and development sub, says Albacore Park Executive Director

Dean Savramis.

When

the Albacore was built in 1952, a mere seven years after the end of

World War II, submarines were seen as surface ships that could also

submerge but for shorter time spans. They were also noisy, slower and

difficult to maneuver. More importantly, enemies could more easily

detect submarines under water.

“After

World War II, the Navy thought that the submarine could serve as a real

deterrent for future conflicts, but it needed to be a true underwater

vessel. It needed to be fast, it needed to be maneuverable, and it

needed to be quiet to avoid detection or minimize the ability for it to

be detected. So that’s what the Albacore was,” says Savramis, a licensed

professional engineer with a background in physical sciences.

The

Albacore’s design was meant to improve upon the capabilities of

previous submarines — her motto, praenuntius futuri, means “forerunner

of the future.”

But its specialized “teardrop” hull design made the Albacore stand out even further.

“What

it’s most famously known for is what’s called a teardrop hull. The hull

design is very different and looks like a teardrop from front to back,”

says Savramis.

That design, says Savramis, allowed for greater maneuverability and speed, which it did to some acclaim.

“It

broke the world speed record for an underwater submarine on two

separate occasions during its service life,” says Savramis. According to

Albacore Park’s website, the submarine reached underwater speeds of

almost 40 mph in 1966.

The

Albacore was also quieter. And its steering system, built in the stern

of the boat, allowed for better maneuverability and control. Savramis

says its design is still the standard for modern submarines.

Bulger says if this 3D technology had existed years ago, it could have been influential as well.

“If not perfectly designed, a propeller will not rotate correctly, causing vibration, resonance and eventual destruction of the design. 3D scanning can detect defects in the materials that could later cause vibration or eventual malfunction or breakage,” Bulger says.

And it’s still unknown as to what future technologies may reveal.

“Albacore pioneered improvements in submersible maneuverability and speed, marking a pivotal moment in technological history. Technologies of tomorrow may even build on concepts that do not yet exist,” Bulger says.

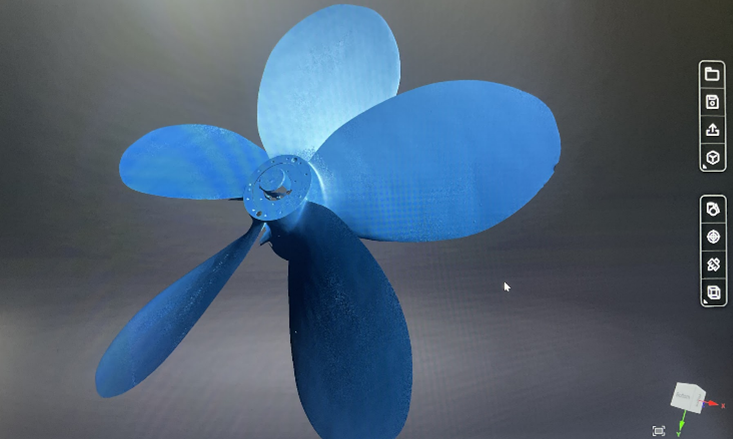

TrueProp created this 3D rendering of a 168-inch (14 foot) propeller that was once attached to the Albacore. (Photo by Dan Freund)

Kaplan reiterates that this line of work is a “niche industry” that’s not well known.

“There’s no propeller school you can go to. In our industry, you got to build people up from scratch, or you got to steal them from someone else’s company, because there’s not that many people that are super knowledgeable about propellers,” says Kaplan.

So any chance they can get to teach younger generations about STEM careers, they take it.

“I think giving back to the community and kids, so that they can maybe pursue a deeper understanding of it down the road, is critical,” says Kaplan.

The park has plans to move further toward that goal. In May, the Portsmouth Submarine and Maritime Association board of directors approved the decision to launch a “center of excellence” at Albacore Park that aims to motivate students to pursue STEM education and skilled trades.

Plans are still under way, but Savramis says they expect to post displays at the park that spotlight the sub’s technological features and explain which trades were used to construct it by the time school resumes at the end of the month.

The goal, says Savramis, is to make STEM careers accessible to all.

“Not everybody has the desire or the means to go to college, but that doesn’t mean you can’t pursue a career in some type of high-tech industry,” he adds.

And these hands-on skills are still in demand, some more than others.

“What I’ve been told is, one of the biggest limiting factors in our manufacturing capability is there’s not enough welders in the country. It’s a real choke point in terms of how much we can manufacture and produce. There’s a lot of interest in promoting careers in those fields, as well as in science, technology, engineering, mathematics,” says Savramis.

At TrueProp, Kaplan works with specialists at propeller shops locally and around the world that support this technology, acting as a member of the service industry for marine propeller inspection.

When explaining propeller technology to first-timers, Kaplan uses the analogy of a car repair shop, where one person might look at the engine, another at the tires. It’s the same concept with a vessel — one person looks at the propeller, another looks at the boat’s engine.

“It’s kind of a niche topic and pretty heavy,” says Kaplan.

Adam Kaplan, chief technical officer of TrueProp, scans the surface of the USS Albacore’s former propeller to locate any damage. (Photo by Dan Freund)

Sometimes, propeller blades hit rocks and other objects under water, damaging them. Other issues include surface cracks or other unseen damage below the surface that can undermine the propeller’s integrity. A dinged-up propeller can cause vibrations which can later harm other parts of the boat.

Kaplan says TrueProp software “talks” to the machine that measures the propellers, and then creates a status report.

If there’s damage, the propeller is sent to a specialist for repair so that it runs smoothly again.

Sometimes, just like car tires, the propellers need to be balanced.

“It’s common to buy a prop and get it tuned up,” says Kaplan.

The nature of TrueProp’s portable technology (it has a battery pack) allows for on-site inspections. This is ideal rather than the standard procedure, which is to remove a propeller from a vessel, ship it to a repair facility for inspection, fix it, ship it back and then re-install it.

Kaplan says their software can save precious time and money, especially when schedules and deliveries must be kept.

The same principal applies to any vessel, from luxury yachts to ocean freighters all the way to lobster boats, though propeller size does play a role.

“As propellers get bigger, you can imagine, if you’re dealing with something that’s maybe 6 feet in diameter, it doesn’t even fit in a truck bed anymore. So transporting it becomes really tough, not to mention just taking it off the ship,” says Kaplan, who adds that shipyards must use scaffolding and cranes to remove large-scale propellers.

True Prop’s handheld 3D scanners use a grid of blue-light lasers to plot the surface of a propeller that was previously on the USS Albacore. (Photo by Dan Freund)

“If they can avoid having to take that propeller off and send it to the specialist, that’s a huge advantage for them,” says Kaplan.

Built at Portsmouth Naval Shipyard for research and development rather than combat, the 16,000-ton Albacore launched in August 1953.

Throughout its life as a research vessel, the Albacore was often tested at Portsmouth Naval Shipyard to troubleshoot any issues. After modifications were made, it would be sent out again for more testing. It was decommissioned in 1972 and placed at the Inactive Ship Facility in Philadelphia.

About 10 years later, a group of residents spearheaded efforts to bring the sub back to her place of origin. After many challenges, the Albacore was placed on a concrete cradle at Albacore Park, which opened to the public on Aug. 30, 1986.

‘One of the biggest limiting factors in our manufacturing capacity is there’s not enough welders in the country.’