Keene State College, DoD-funded optics manufacturing organization form educational partnership

Just as the textile mills of old once dominated New Hampshire’s production landscape, a new type of manufacturing is taking shape in the state’s Monadnock Region, and it’s finding use in medical, aerospace and national defense applications.

It’s known as diamond-turning precision optics manufacturing, and a new multimillion-dollar partnership developing this year between Keene State College and AmeriCOM (the American Center for Optics Manufacturing) is poised to offer career pathways in the field without a four-year college route, the two organizations announced in connected news releases in May.

The curriculum will be structured through a one-week workshop or a one-year certificate, made possible by more than $1 million in funding from AmeriCOM. The money originates from the U.S. Department of Defense’s Office of Industrial Policy.

Additionally, a new diamond-turning teaching lab will usher in equipment installed on campus, to be named the Kingsbury Center for Diamond Turning Excellence. It’s financed by a $3 million federal grant of Congressionally Directed Spending (CDS) awarded to Keene State, requested by U.S. Sen. Jeanne Shaheen, and by a $100,000 gift the school received from the Kingsbury Foundation.

The foundation was established in 1952 by officials of the Kingsbury Corp., a former machine tool manufacturer in Keene that filed for bankruptcy in 2011.

The partnership builds upon Keene State’s recent history of growing a precision optics program, beginning when the college identified a need for diamond-turning education based on the machines’ use at more than a dozen local employers like AMETEK Precitech Inc., a leading industry manufacturer of diamond-turning equipment headquartered in Keene, and Moore Nanotechnology, a producer of lenses and optics components in Swanzey, which neighbors Keene to the south.

Turning with precision

Diamond-turning optics manufacturing involves using a machining lathe with a diamond tip to create an optical surface on materials like non-ferrous metals (think copper or aluminum) and some synthetics and plastics to create an optical finish, according to an interview on Precitech’s website. This differs from traditional optics manufacturing, where glass is ground and polished using direct machining.

Keene State’s diamond-turning program was originally a grouping of individual courses that taught skills that could apply locally, according to James Kraly, associate dean of academic innovation at Keene State College.

“We initially packaged those together to be part of what we called, ‘micro-credentials,’” Kraly said. “There was a microcredential in precision optics, and there was another in precision optics and manufacturing. We started to attend national meetings on optics education, and I had this really interesting moment where I was at a meeting in Rochester, New York, and took a tour to visit Monroe Community College.”

Making small talk, Kraly asked others onboard the bus where they were visiting from and unwittingly learned they were local to him, getting responses of “Keene” and “Swanzey.”

“It was the beginning of us realizing we’re at the center of a specialized network for precision optics,” Kraly said.

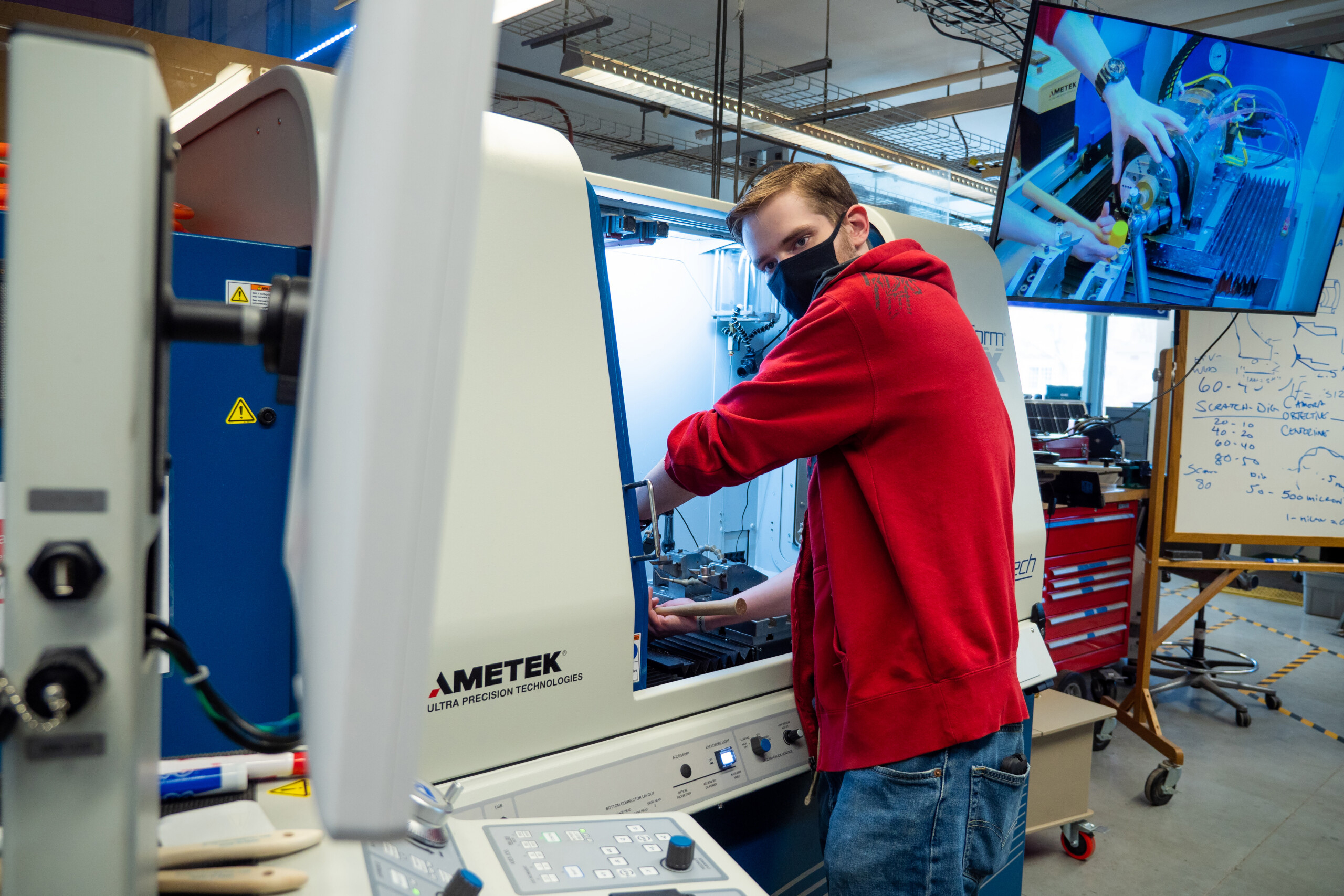

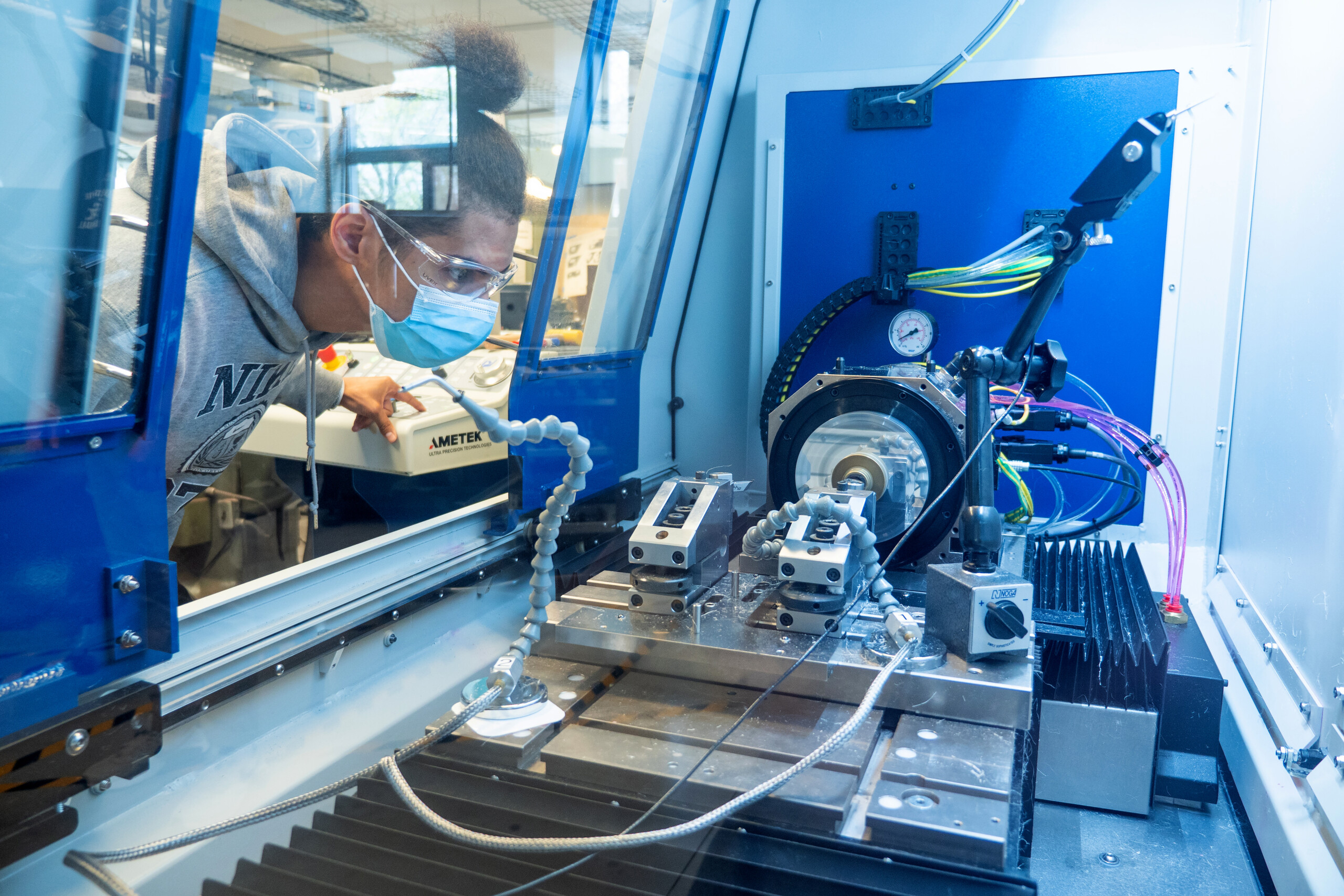

Preitech, one member of that network, previously donated two lathe machines to help kick-start local instruction, one being a diamond-turning instrument known as a Nanoform X.

“We built a class around Precitech’s donation of the instrument, and that led to a successful course over a series of years (that was) really a way for the college to point to our partners to say, ‘Look what we’ve already done, look what’s in place, and help us accelerate this to a new level,’” Kraly said.

A Keene State student uses a Nanoform X, a diamond-turning lathe created by local optics company AMETEK Precitech, Inc. (Photo courtesy Keene State College Marketing & Communications)

A Keene State student peers into the enclosure of a Nanoform X, a diamond-turning lathe created by local optics company AMETEK Precitech, Inc. (Photo courtesy Keene State College Marketing & Communications)

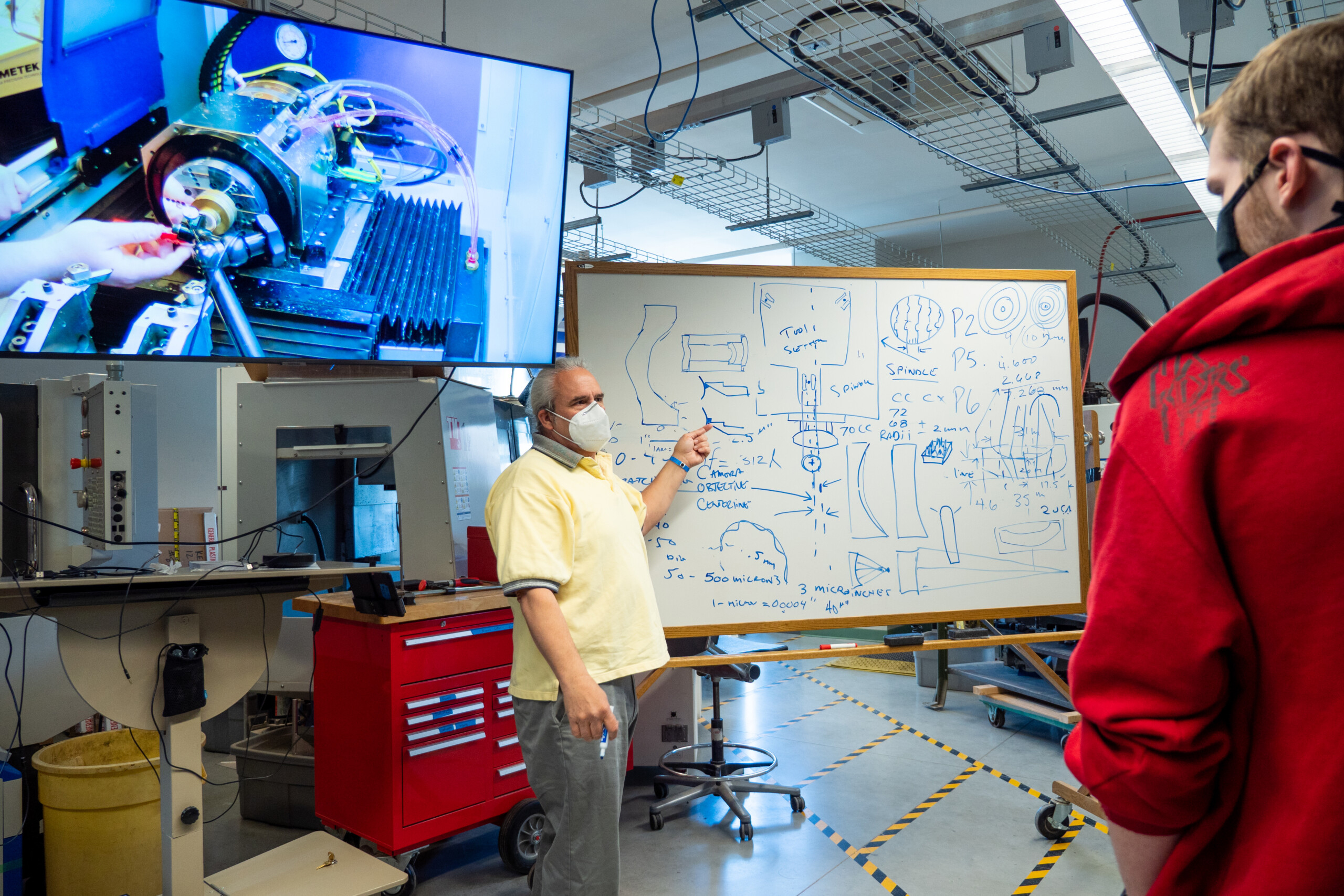

Keene State College professor James Wing describes a diagram of a diamond-turning lathe in a course on the equipment. (Photo courtesy Keene State College Marketing & Communications)

‘A national asset’

The connections Kraly and Keene State made introduced them to AmeriCOM, whose officials were impressed by the educational infrastructure that the college had formed with the surrounding industry ecosystem, AmeriCOM CEO Dave Shelton said.

“Keene is a great national asset, and I didn’t know anything about it,” he said, recalling when he learned of the city’s optics footprint and the college. “It makes a ton of sense for Keene State to be there to step in and train technicians. They’re a four-year college, but they’ve been very flexible and willing to offer a one-year program, which they wouldn’t normally do.”

Keene State is the first four-year institution to partner with AmeriCOM, which until now has supported optics education solely at four community colleges in New York, Colorado, New Jersey and Florida. As these have been two-year associate’s degree programs, Kraly said this program opens new doors for Keene State.

“It’s a one-year program that culminates in a local internship, so it still has these identities of what we highly value at Keene State — high-impact practices of working closely with faculty, local industry and it’s still going to have foundational courses as part of that,” he said, like math and business classes that already exist at the school.

Additionally, faculty already teaching optics courses will be part of this program while bringing in industry professionals to offer students supplemental instruction like seminars, Kraly said, starting with a five-day workshop in January.

In the meantime, Kraly said the lab is being built this summer and fall, with hopes for a fall semester launch. That space is being repurposed from a large storage area, staff office and underused computer lab whose equipment will be relocated to create an augmented reality and virtual reality lab for architecture and construction management students, he said.

Shelton expressed openness to AmeriCOM working with other four-year colleges and universities if the opportunity arises, based off Keene State’s outcome of the program.

“Keene State, I think, is really going to be a shining star and a great example of this type of program for AmeriCOM, so we’ve very delighted with it,” Shelton said.

More on AmeriCOM’s work in optics education can be found at www.thefutureisoptics.com.